Greetings!

Hello Fellow Designers from IDSA,

Welcome to my page, where I have compiled both my latest projects and some of my earlier works. The aim is to facilitate an easier review of my portfolio. My name is Isaque Verissimo, and I hail from São Paulo, Brazil. I have been immersed in the design world since 2007, beginning with graphic design while I was pursuing a Bachelor's degree in Graphic Design.

Ultimately, I left that university after the 3rd term, and completed a a professional design certification degree at Panamerican School of Design in São Paulo. I further expanded my knowledge by attending an intensive filmmaking program at the New York Film Academy in Los Angeles, focusing on production design. I have also completed numerous other courses and trainings to enhance my skills, such as Class A Alias Studio Modeling Training, Cinema 4D, Blender, and Automotive Engineering Concepts.

Post-2013, I followed my dream of designing and building cars, transitioning fully to industrial design. I have continually educated myself and evolved my abilities in this field. In 2014, I founded Verissimo Design Studio with my brother, a skilled builder who has been instrumental in realizing all of my designs since we began. I hope you enjoy exploring my work. Please feel free to contact me if you have any questions.

Thank you,

Isaque Verissimo

Auto Design

ExoNB Racing UTV / Giaffone

The challenge was to design the body for the new Giaffone Racing UTV Chassis.

They afforded me considerable creative liberty, and after numerous sketches and extensive meetings with the engineering department, we finalized the design.

Given its use in rally racing, I designed all components as modular units to simplify repairs during the championship events.

The fairing molds were expertly crafted by my brother, Stevão Verissimo, who made an exceptional woodwork to precisely fit the chassis.

The ExoNB represents a significant innovation. It is the first chassis made from Niobium-Steel and became the first electrified vehicle to compete in the Sertões Championship, the second-largest rally event after the Dakar.

Creation Process

Official Launching Video

Sketching Timelapse

Concept Sketching

Final Car

Racing UTV / Giaffone

During my first meeting with the Giaffone team, I presented them with a unique concept, which was very well received and published in the media as part of their UTV program announcement. However, due to some technical limitations, the design direction had to be changed. Nevertheless, I am pleased with how the project started.

VNT RC Y21 // Beira Rio / AVF

I designed an all-new racing car for the VNT Racing Series, in partnership with Beira Rio, a renowned race car construction company.

The goal of this car was to have a lower drag coefficient compared to its predecessor. To achieve this, we relocated the radiator behind the driver, allowing for a much sleeker rear-end that minimizes air turbulence. This redesign posed a significant challenge in terms of cooling. The new position of the radiator necessitated strategically placed air intakes on the sides, which unfortunately caused additional drag. To find the right equation, I conducted simulations using computational fluid dynamics software to optimize the balance between downforce and drag.

I began with initial sketches and ideations, then proceeded to model the entire car in Alias Studio. Subsequently, all models were precisely milled using a CNC machine, ensuring the project's accuracy and precision.

The result is a car that is not only faster but also more elegantly designed than the previous model, and did really well on the track.

Concept Sketching

Development Process

Final Car

VMX // MAGNETAR

The Magnetar Program is under development as a rear-wheel drive sport electric vehicle. I was commissioned to design this car to be the very first all-electric racing category in Brazil. I also would have to feature a street-legal version.

I designed it to be super spartan and yet elegant. It also had to be able to be converted from a single central seater to a two-seater configuration, proposing some challenges in finding the best cabin proportion.

Unfortunatly, my client at the time got financialy stuck after the pandemic and pro project didn't succeded yet. Instead, it gave birth to the Trellus project that is under development right now.

Design ideation

Concept Sketching

Design Ideation

TRELLUS MOTORS

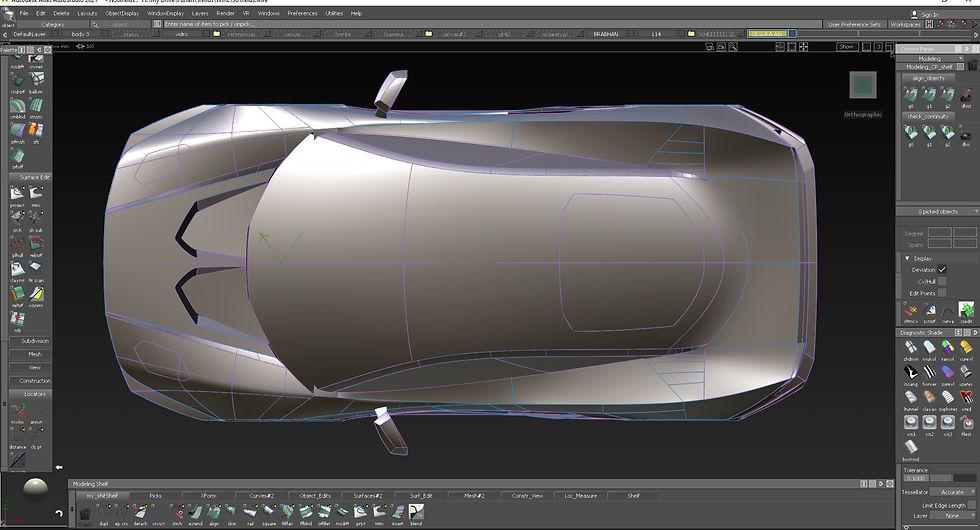

Following the Magnetar project, a Brazilian start-up company commissioned me to design a new car using the same concept. I got approval for the very first conceptual sketch I presented. Then, I moved on straight to the class B alias modeling and preparation for the robotic milling process. The car is right now under development with a team producing the molds for the prototype.

Alias Class B Modeling

Robot Milling and Mold Making (Under development)

VMX // Kart Cross

I partnered with two-time national champion driver, Felipe de Nadai, to build a new racing car for the Kart Cross Racing series. Despite the strict regulations imposed by the Brazilian Automobilistic Confederation regarding dimensions and other aspects, we managed to design an innovative car that proved to be faster, lighter, and more resistant than all other cars on the grid.

We achieved this by positioning the driver on a level table in the optimal spot and then designing the car with wires around him. I created the initial design in SolidWorks and worked alongside an engineer to simulate and refine all the geometries, including the Ackerman steering geometry, pro-dive suspension geometry, and rolling control for precise cornering.

We also run FEA (Finite Elements) Simulations on the chassi to optimize its strength and natural frequencies incidence.

For the fairings, we transformed the sketches into a precise scale model in clay, which I then had 3D scanned. I modeled the surfaces in software to be precisely milled.

As a result, our car shaved nearly a whole second off the time of the championship-winning car in tests.

Concept Sketch

Development

Final Car

V8 Rally Buggy // Giaffone Racing

In partnership with Giaffone Racing, we designed and manufactured the new fairing for the V8 Off-road Buggy. This 4x2 vehicle features a rear-mounted V8 engine, similar to those used in the Stock Car category. It is undoubtedly the largest and most robust off-road vehicle ever developed in Brazil.

The most challenging aspect of this project was the placement of the huge V8 engine on the rear axle overhang, which dramatically increased the size of the rear end. This made it quite difficult to design a truck-looking car without awkward rear proportions. I employed some tricks, such as extending the tubular protection around the engine and keeping the read end of the fairing open, maintaining harmony with the bodywork.

We crafted the design based on a chassis developed by JL. We went from the dimensional sketch over the orthogonal view of the chassis, straight to a scale clay model, and then, to the woodwork, which was my brother's preferred technique to fit such a huge car.

Concept Sketching

Clay Model

Fairing molds construction

Development Process

Final Car

VERISSIMO TEYU LSC

Named after a very aggressive Brazilian lizard, I envisioned a lightweight car that would stand out.

Inspiration came from this reptile, known for its aggressive look and remarkable ability to accelerate powerfully with extreme agility and precision, much like its rear legs enable it to do.

I designed this car as a light ports car meant for the track but also street-legal. My goal was to blend the European concept with an American formula, featuring a light V6 engine mounted in the front.

It was designed to look elegant and be super fun to drive. The prototype performed really well.

3D Model

Prototype

AVF Racing RCY14

The AVF RC Y14 was the very first automotive project that I designed and built. We were commissioned to build a new fairing over an existing chassis. I had a lot of freedom in designing it. The final result featured improved cooling, which allowed the cooling fans to run less often during races, effectively increasing power by up to 5 hp.

Five cars were built, and two of them won endurance championships and national championships in the subsequent years.

Development Process

Project Gallery

Aviation

Seamax // Concept

Concept Sketching

I was asked to create a new concept by the aircraft manufacturer, Seamax. This plane is a 5-seater capable of lifting 1 ton of cargo and can be converted into a cargo plane, including a firefighting version designed to operate in swarms.

Aircraft design is always influenced by aerodynamics, with aesthetics often following computational fluid dynamics (CFD) simulations. Within these necessary aerodynamic constraints, I crafted lines, window panes, and cuts that gave the aircraft a more futuristic look, moving away from the commonplace styles that make many aircraft seem like they're from the 70's.

The cockpit windows were designed to maximize the pilot’s vision and to facilitate production of acrylic parts, which were divided into three separate panels.

Lightweight Firefighter Concept

Helvetica Light is an easy-to-read font, with tall and narrow letters, that works well on almost every site.

Seamax // Vertical Connect

/2023

I was called upon to formulate a strategy for using a robotic arm to mill the volumes needed to produce an exhibition mockup for an aerial vehicle. My role was limited to consulting on the production of the mockup, using the model already provided by the client.

It has been an interesting project to work on. It is currently under development, and I am actively working on a new approach for the vehicle.

Mockup Production

Educational Robotics

Asteroid Rover

We were asked to design a robotic rover for an educational program aimed at introducing robotics to children between the ages of 9 and 12.

The challenge was to create an affordable robot that could be easily replicated. We decided to design an innovative chassis using 3D printing and off-the-shelf parts.

Along with the robot, we developed an itinerant platform that simulates the surface of an asteroid. The program has been deployed in schools, universities, and events, inspiring hundreds of kids worldwide.

Since it was 3D printed, I had great flexibility to experiment with the design. Intended to spark interest in young students, I aimed to tell a futuristic story through the design of the robot, which features an organic yet technical appearance.

Robot Testing (Video)

Assteroid Mission Program Highlights (Video)

Development and deployment

K-Rover

The K-Rover is an educational robotic rover developed by Estúdio Verissimo in collaboration with Michaellis Foundation For Global Education

The "K" in K-Rover stands for 1000, symbolizing the over a thousand possible applications for this versatile robotic rover. It is specifically designed for educational programs aimed at introducing robotics.

Constructed from aluminum and composite materials, the K-Rover allows students to assemble the rover using real tools, thereby developing essential skills in engineering and industry.

Development Video

Development

Medical

Tesk Medical

Here’s your text with enhanced clarity and corrected grammar:

I was asked to provide some visual propositions for a family of medical products for Tesk Medical Company. This included a consciousness monitor for surgical procedures, electro-monitorization equipment, and a migraine relief device that works through controlled stimulation of the vagal nerve.

Considering the likelihood of blood spills and the need for durability to withstand the demanding medical environment, I opted for a clean and minimalistic approach. All products are made from machined aluminum and engineering plastics. I also proposed the interface concepts.

These concepts were well received and are still in development.

Concept Sketching

Thank you

I appreciate the time and effort you took to review my work. Please don't hesitate to reach out if you have any questions.

+55 19 993389786